Imagine a city where façades breathe in harmony with nature – buildings not only protect and adorn the environment but also reduce the carbon footprint, use local resources, and support the circular economy. Such an urban environment would not only be aesthetically appealing but also ecologically balanced, demonstrating how scientific achievements can be harmoniously integrated into everyday life.

To realise precisely this vision, researchers at the Latvian State Institute of Wood Chemistry are currently developing innovative biobased particleboards for façade applications. The first results of the study have been published in the open-access international journal Forests.

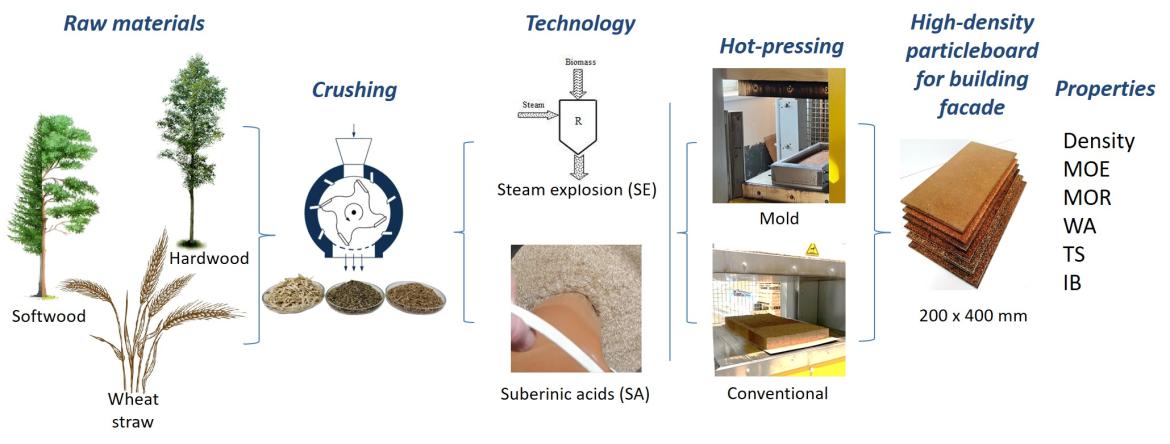

The construction sector currently consumes at least 40% of total energy and generates a similar share of greenhouse gas emissions, which makes the development of new, environmentally friendly solutions particularly important. In the article “Physical–Mechanical Properties of Innovative Biobased Particleboards for Application in External Building Facades”, authors Dr.sc.ing. Ramūnas Tupčiauskas, Mg. sc. ing. Andris Bērziņš, PhD Mārtiņš Andžs, Mg. sc. ing. Rūdolfs Bērziņš, Dr.sc.ing. Jānis Rižikovs, and Dr.sc.ing. Gunārs Pavlovičs analyses the properties of high-density particleboards developed from local resources – wheat straw, grey alder, and softwood (spruce and pine). This study particularly highlights the potential of Latvia’s bioeconomy, enabling the use of biomass available in our own fields and forests to create high-value-added products of international relevance.

Two innovative technologies

The study employed two approaches, which can be compared, for example, to cooking techniques in the kitchen. Steam explosion treatment works on the “pressure cooker” principle: wood and straw raw materials are subjected to high pressure at elevated temperature and then suddenly “exploded” by releasing the pressure. In this process, the lignocellulosic material becomes softer and more elastic, and the explosion turns it into a fibrous mass with a modified chemical structure that could be bonded without additional adhesives. Panels produced from this fibremass can be binder-less – just like sourdough bread that holds together without added yeast, thanks to the natural interaction of flour and microorganisms.

The second approach uses suberinic acids obtained from birch bark processing, which serve as an environmentally friendly alternative to synthetic adhesives.

Both materials were then formed using two pressing techniques: conventional hot-pressing and mould hot-pressing. This combination of approaches enabled researchers not only to compare different raw materials but also to evaluate how the production process affects the final product’s density, water resistance, and mechanical properties.

Key results

The results of the study showed significant differences between the raw materials and technologies used. The best physical–mechanical indicators were achieved with conventionally hot-pressed alder panels after steam explosion treatment, with densities reaching up to 1380 kg/m³. Bending and elasticity properties in all cases exceeded the requirements of the European standard EN 312, in some cases even two- to fivefold. In water resistance tests, standards were met only by steam-exploded alder panels, confirming this raw material’s particular suitability for external façade applications. Wheat straw panels demonstrated lower performance; however, their mechanical properties improved significantly when suberinic acid adhesive from birch bark was used.

Alder, straw, and birch bark – next-generation building materials

This study was carried out within the framework of a project funded by the Latvian Council of Science (lzp-2023/1-0348). The project’s goal is not only to create new prototypes of biobased materials but also to assess their practical applicability in construction, especially in façade systems, which are one of the most essential elements for improving building energy efficiency.

Such work demonstrates the ability of Latvian researchers to address global challenges using local resources and knowledge. By utilising alder, wheat straw, softwood, and birch bark derivatives, materials with high added value are created while reducing dependence on fossil resources. This is a step toward construction based on bioeconomy principles, with a lower carbon footprint and stronger links to Latvia’s natural resources.

The project results show that innovative technologies could be moved from the laboratory bench to real products with the potential to improve urban quality and construction sustainability. This approach strengthens the role of the Latvian State Institute of Wood Chemistry not only as a centre of science but also as a creator of practical solutions on an international scale.

Dr. Ramūnas Tupčiauskas: "Our goal is to use local biomass and birch bark derivatives to create an alternative to unsustainable synthetic adhesives and cement currently used in façade materials, thereby promoting climate neutrality in construction."