Fish processing generates a large amount of biological by-products which, depending on the species and processing method, can account for 30–70% of the total fish mass, and the efficient utilisation of these streams remains a significant challenge for the industry (EUMOFA, 2025*). At the same time, the need to replace plastic packaging with more environmentally friendly solutions is becoming increasingly pressing. The idea of the project “Isolation of fish protein hydrolysate and its condensation with plant catechol derivatives to develop improved starch/protein-based food packaging” (No. 23-00-U2021902-000001), implemented at the Latvian State Institute of Wood Chemistry, lies at the intersection of these two challenges: is it possible to develop new food packaging materials from locally available, low-value biological resources?

In the project, scientists from the Latvian State Institute of Wood Chemistry collaborate with the Kuiviži Fishermen’s Association, using fish biomass and wood resources sourced in Latvia. Fish protein hydrolysate—a mixture of proteins and peptides—is obtained from fish processing by-products and serves as a potential raw material for the development of new biopolymer materials. In parallel, our researchers extract natural compounds containing catechol moieties from black alder and pine bark.

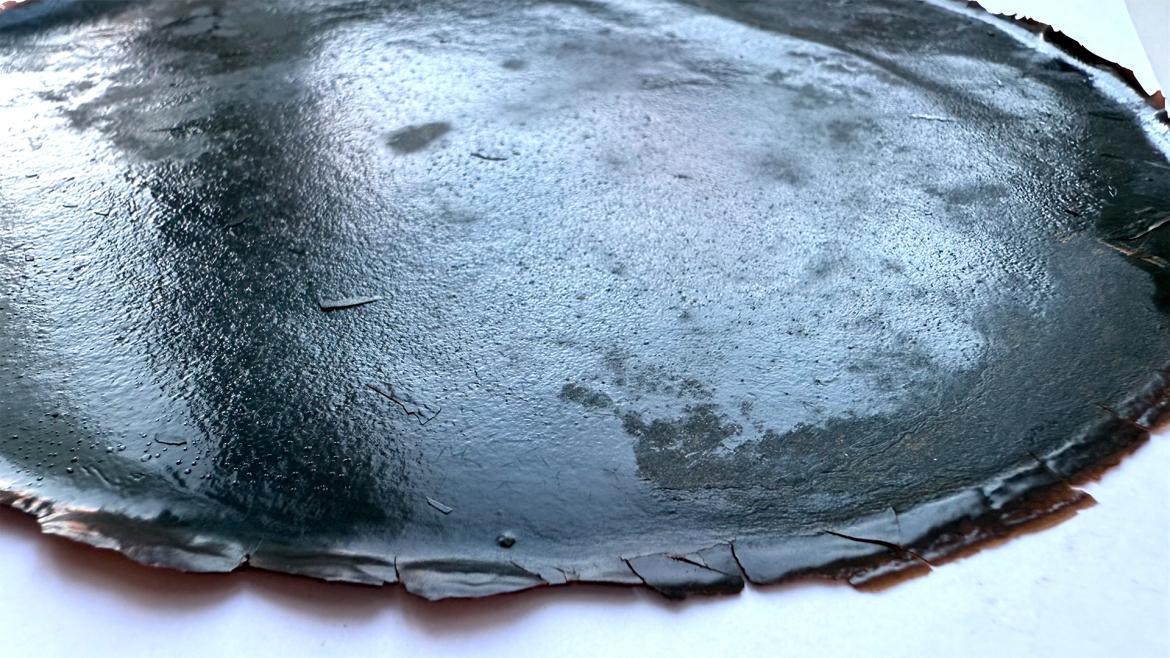

In the laboratory, these two components—fish proteins and tree bark extracts—are combined to form thin biopolymer films. Such films represent potential prototypes for packaging materials. During the study, various compositions and processing conditions are investigated to determine how to obtain materials with improved mechanical strength and flexibility.

The results obtained so far have shown that the process is not straightforward and that not all approaches perform equally well. For example, films produced from fish protein hydrolysate were found to be flexible but mechanically weaker than films made from collagen or gelatin. The project coordinator, Dr. chem. Māris Lauberts, emphasizes that this can be explained by the structure of fish protein hydrolysate: the peptide chains it contains are relatively short, which makes it more difficult for them to form a stable material matrix. Nevertheless, these findings are an essential part of the research, as they clearly identify the key challenges and indicate the directions in which further development is needed.

“In future studies, we plan to improve the structure of the fish-derived material to make it more durable. This will involve isolating high-molecular-weight fractions from fish biomass, as well as using high-molecular-weight proanthocyanidins from pine bark as a natural source of catechol units,” explains Dr. Lauberts.

An important component of the project is collaboration and knowledge transfer. The involvement of fishermen in the preparation of fish biomass, together with the work of scientists in the laboratory, makes it possible to evaluate the entire process—from raw material acquisition to material testing. In parallel with the research, our scientists have delivered lectures to school pupils and students and participated in public outreach events, where they explained how science can help address practical environmental and resource-use challenges.

The project will continue until mid-2027, with the aim of gradually bringing scientific solutions closer to practical application. The results achieved so far, as well as the research process itself, demonstrate that even seemingly low-value biological by-products can form the basis for innovation in future packaging materials.

European Commission’s European Market Observatory for Fisheries and Aquaculture Products (EUMOFA), 2025